Skalar has successfully installed a SP2000 beer analysis robot at Brauerei C. & A. VELTINS GmbH & Co

Beer brewing is an art, involving the measurement of important parameters for guiding the brewing process towards the desired flavors and character of the beer to be brewed.

Such a parameter is the bitterness of the beer, which stems from compounds such as humulones or alpha acids from hops used during brewing. Various other parameters are monitored to control the brewing process, result and quality. In case of Brauerei C. & A. VELTINS, additional parameters are for example, Free Amino Acids (FAN), Anthocyanogens, SO2, Polyphenols and Thiobarbituric Acid Index (TBI).

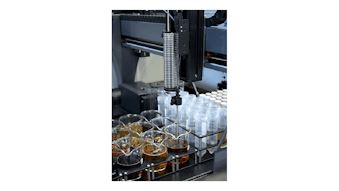

A reliable and widespread method to measure beer parameters is spectrophotometry, according to international methods such as EBC, ASBC, Mebak and others. The Brauerei C. & A. VELTINS laboratory in Meschede, Germany, uses the SP2000 robot for the automation of their spectrophotometric analysis in the various types of beer and wort samples

Reasons for automating the analytical process with a SP2000 beer robot:

Reduce the workload for the laboratory staff.

The robotic analyzer takes care of all the necessary steps for a complete unattended automation of the analysis. The operator inserts the beer/wort samples and starts the robot.

Higher flexibility for larger product variety.

The robotic analyzer uses absolute methods according to the accepted international methods and therefore does not need to be calibrated each time an analysis is started. This makes it easier to analyze smaller sample batches, resulting from a larger product variety of beers in the market today.

Multiple parameters on one platform.

The robotic analyzer has a flexible set of parameters, which can be used, according to the analytical requirements of each day.

Analysis according to international methods such as EBC, ASBC, Mebak.

The robotic analyzer replicates the procedures fixed in the relevant norms 1:1. At the same time variations of a method can easily be programmed into the system through the Skalar application support team.

Features:

- Complete automation includes: degassing of the samples, (de)-capping the sample tube, sample dilution, addition of reagents, mixing and measurement of the absorbance

- Batch-wise analysis, which fits perfectly into each brewery production site

- Flexibility to process small or large batches and run single or multiparameter analysis

- No calibration required for Bitterness value calculation

- Can be used for various types of beers with low and high bitterness values

- Iso-octane reagent consumption of the automatic bitterness method is reduced by a factor of 5 compared to the manual method

- Possibility to combine the bitterness application with pH, color, FAN, SO2 etc.

- RoboticAccess™ software for instrument control, data handling, result calculation and QC

- Methods according to EBC, ASBC, Mebak, etc.

For more information about beer analysis with our SP2000 robotic analyzer or other applications, please feel free to contact Skalar.